For unique configurations you can purchase quality Tuf-Flex or Tuf-Flex Ribbed material in roll stock. Widths from 4″ to 48″ allow you to cover any size openings. Thickness from .04 mill to .160 mill can help you overcome height or pressure differences with your application. Colors are not just aesthetic although they can certainly make a application look sharp.

If you choose to work with bulk roll vinyl material to create barriers consider the following attributes as you make your plans.

Size & Thickness

| Traffic Type | Suggested Use | Strip Overlay | Thickness |

|---|---|---|---|

| Light – 4″ Strips | Interior partitions and enclosures, splash barriers, conveyor openings and assembly lines. | 50% | .060″ |

| Light – 6″ Strips | Interior doors to 10′ high and exterior doors to 8″high. Interior partitions and enclosures, splash barriers, conveyor openings and assembly lines. | 50% | .060″ |

| Light – 8″ Strips | Interior doors to 10′ high and exterior doors to 8″high. Interior partitions and enclosures, splash barriers, conveyor openings and assembly lines. | 50% | .080″ |

| Medium – 12″ Strips | Interior doors and exterior doors from 10′ to 15′ high. Noise enclosures and secondary cooler doors. | 67% | .12″ |

| Heavy – 16″ Strips | Heavy equipment traffic doors 14′ and higher. Maximum noise control. | 75% | .16″ |

| This chart reflects general suggestions only. Your application, special circumstances and size of strip doors needed may change the above suggestions. Call for assistance. | |||

Ribbed VS Smooth

Not rocket science here. Smooth offers best visibility and works well where there is little air current. Interior openings, etc. Ribbed offers more resistance to parting and when used with higher overlaps will be the best choice for wind or air current.

Material Type

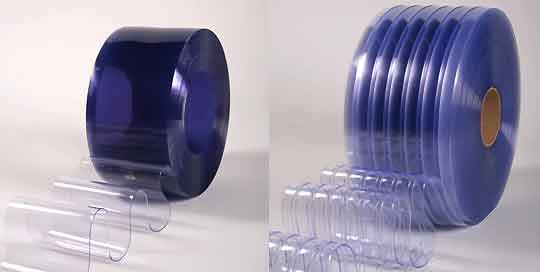

Prefabricated PVC rolls are the fastest, easiest way to replace worn vinyl strips in your existing strip door. Full length vinyl rolls with individual strips perforated at the length specified by the customer at the time of order. Mounting holes pre-punched on 2″ centers in the strip for Kwik easy installation.

-

-

Standard Clear

For use in interior and exterior applications above freezing. 30 degrees (F) to 150 degrees (F)

-

Standard Clear Ribbed

For use in interior and exterior applications above freezing. More durable than Standard Clear and scratch resistant.

-

Low Temp Clear

For use in interior applications in ranges of -30 degrees (F) to 100 degrees (F)

-

Low Temp Reinforced

For use in interior applications below 40 degrees (F).

-

Low Temp Clear Ribbed

For use in interior applications below 40 degrees (F). More durable than Low Temp Clear and scratch resistant.

-

Safety Orange

To outline parts of doors that are unsafe for passage because of nearness to walls, irregular aisles, etc.

-

Kwik Strip

Prefabricated PVC rolls are the fastest, easiest way to replace worn vinyl strips in your existing door. Full length vinyl rolls with individual strips perforated at the length specified by the customer at the time of order. Mounting holes pre-punched on 2″ centers in the strip for kwik easy installation.

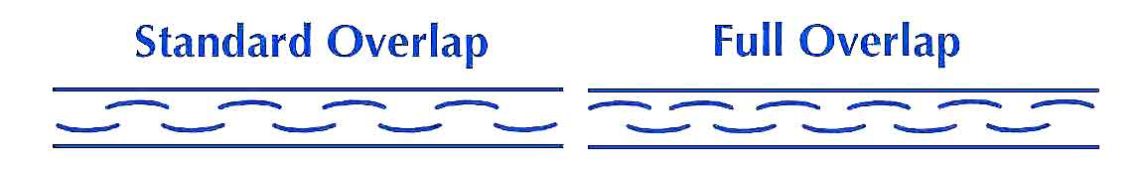

Overlap